One of the world’s largest automakers with a long-standing legacy of revolutionizing car manufacturing. The company produces millions of cutting-edge passenger cars, commercial vehicles, and luxury cars every year.

Get mission-critical predictive insights from massive volumes of diverse data

The automaker wanted a predictive maintenance solution that would pre-empt faults in tools which played a crucial role in creating vehicle components. They were looking for a real-time solution that would:

Process and analyze millions of events generated every minute from thousands of machines

The automaker’s manufacturing units were generating large volumes of diverse data in multiple discrete systems, all of which had to be integrated and processed simultaneously to analyze the tools and predict their end of life.

Data quality concerns

The data collected from multiple systems had several quality issues and missing records. This data had to be formatted, cleansed, and prepared before it could be fed into predictive models.

Massive scale

The automaker needed to process massive amounts of data in real time using a single solution and shared infrastructure.

Delayed alerts

Getting real-time alerts on tool health was crucial for floor operators across the manufacturing units. Any failure or delay in these alerts had a direct impact on the quality and delivery time of vehicle parts.

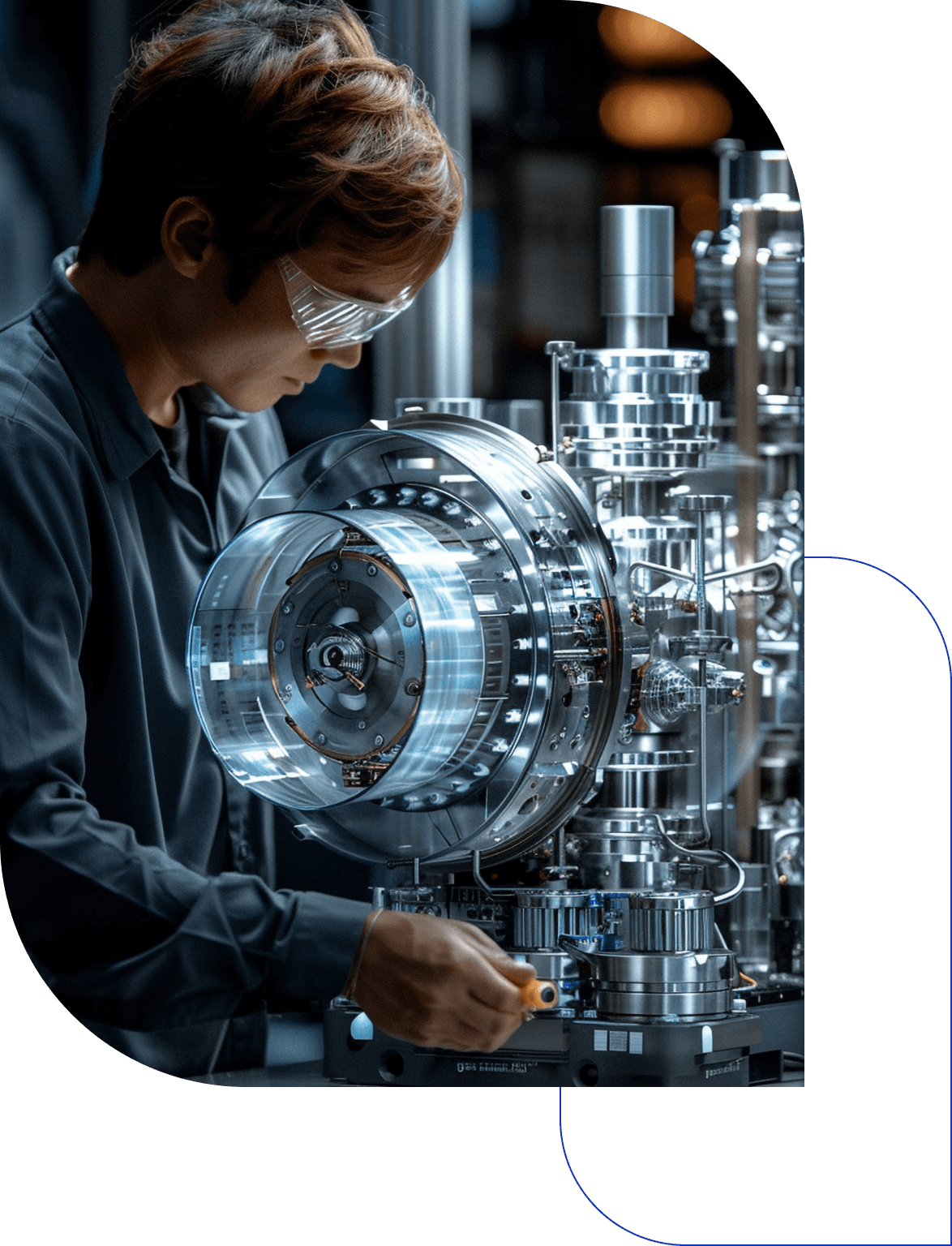

A unified, real-time predictive maintenance solution

The automaker deployed Gathr.ai in their manufacturing division to collect data from various sources, transform and analyze it, and predict the life of mission-critical tools used to create auto parts. We implemented a unified predictive maintenance solution with the following ready-to-use capabilities:

Real-time data ingestion

Ingested real-time data from IoT sensors and logs, along with vendor information from legacy databases and historical tool records.

Data cleansing and integration

Handled inconsistent data, imputed missing values, filtered erroneous records, and unified data coming in from diverse sources.

Data transformation and online scoring

Created interaction terms for new features, encoding categorical ordinal and nominal variables, while enabling real-time scoring.

Predictive insights

Delivered recommendations on the optimal replacement time for failing tools.

Real-time alerts

Set up custom email alerts highlighting severity levels based on the number of days left for replacing tools.

Monitoring and dashboards

Helped visualize the health of tools and monitored assembly lines in real time.

Enabling faster delivery to dealers and customers with predictive analytics

Gathr.ai delivered a unified predictive analytics solution with a single pane to monitor tools across all assembly lines and ensure fault-free production. This in turn helped their vehicles reach dealers and customers significantly faster.

Gathr.ai’s predictive maintenance solution has played a crucial role in ensuring fault-free production across our assembly lines. It has helped us minimize defects, accelerate delivery timelines, and ultimately boost customer satisfaction.

Senior Director

Manufacturing Operations

Senior Director

Manufacturing Operations

Gathr.ai’s predictive maintenance solution has played a crucial role in ensuring fault-free production across our assembly lines. It has helped us minimize defects, accelerate delivery timelines, and ultimately boost customer satisfaction.

Redshift

Redshift MS SQL

MS SQL  MySQL

MySQL PostgreSQL

PostgreSQL Trino

Trino Starburst

Starburst

All resources

All resources